Manual Crimping

AP93L Manual Crimping Machine

Manual crimping machine AP93L is simple to use and recommended for a limited daily production. It is a counter machine, built with a solid structure which supports the crimping head (available FEA standards 11,13,15,17,18,20mm) and a plate where to place bottle. One rotation movement of the lever (approx. 100°) allows the approaching of the head over the bottle and pump and the crimping operation. This machine can also be fitted with a collar pressing head, upon request.

Semi-Automatic Crimping

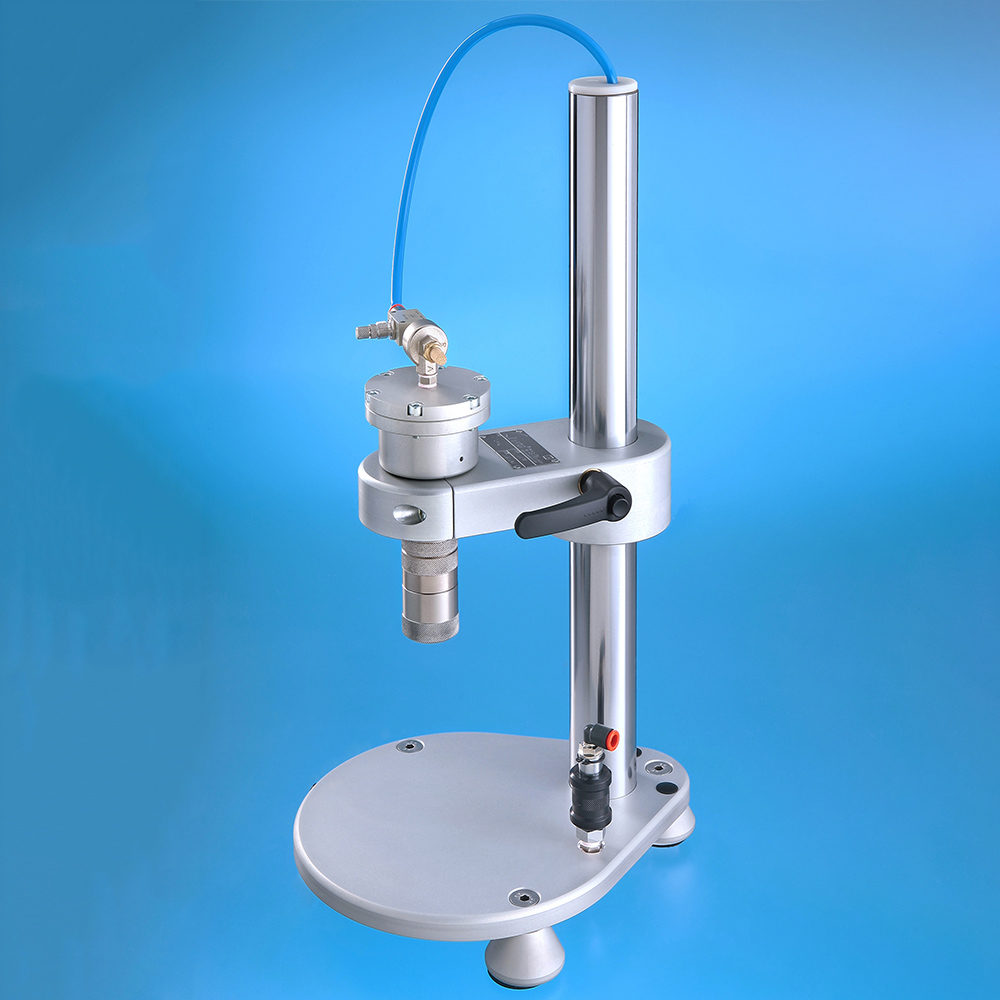

AP01 - Pneumatic crimping machine

Pneumatically operated semi automatic crimping machine AP01 is suitable for both glass bottle and aluminum 1” aerosol can crimping. This machine is recommended for medium scale production numbers. AP01 is the only pneumatic machine, within our range, that allows the crimping of aluminum aerosol cans by a simple lever movement. When crimping aerosol cans, please note that AP01 crimp valves internally and only prior to the gas filling operation.

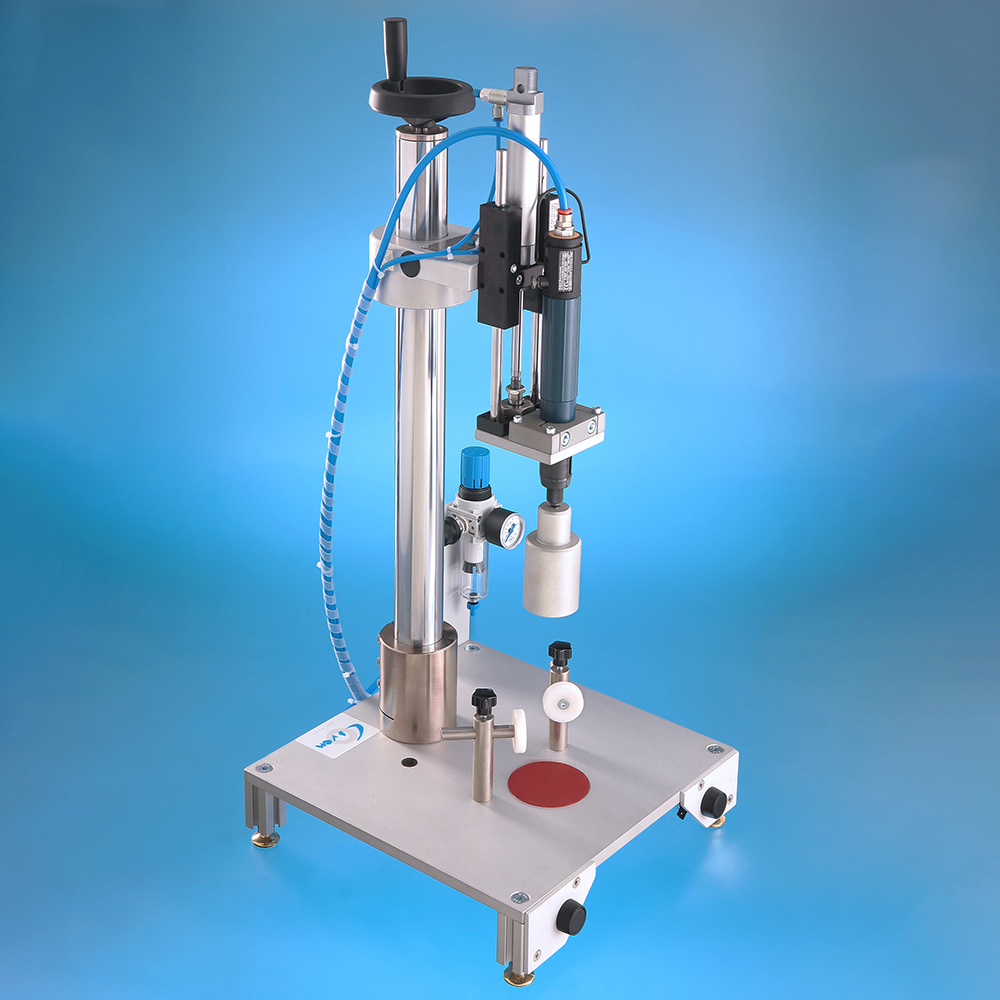

AP02 - Pneumatic crimping machine

Semi-automatic, pneumatic crimping machine AP02 is the right compromise between quality and price for a medium - high production. Versatility and simple use are its main characteristics. Suitable for FEA perfume standard diameters 11,13,15,17,18,20mm. The special features of this machine are the large aluminum base and a set of “catch hands” which hold the bottle in position while crimping. This feature is particularly indicated for tall and narrow bottles, as the catch hands act like a pre crimping operation.

Screw Tightening Device

AV11 - Pneumatic screw tightening machine

Semi-automatic pneumatic screw tightening device AV11 is handy, versatile and of simple use. It is suitable for glass or plastic bottles with screw caps. The main body is adjustable in height and it is fitted with a Bosh pneumatic screwdriver with torque from 1,2 Nm to 10 Nm - 380 rpm (round per minute) without load. This machine is able to be adjusted in the tightening power and it is fitting to various types of tops. The absence of electrical parts makes the use of AV11 safe in any environment.

Decrimping Machines

CR12 - Pneumatic Collar Remover

CR12 is a pneumatic counter machine able to remove collars of standard diameters from a crimped bottle without any damage to the bottle or to the pumps. The actuator needs to be manually removed prior this operation. The machine is pneumatically operated and of simple use, recommended also for “crimp-less” pumps removing operation. The special head on this machine can also be supplied separately for existing production lines application.

The absence of electrical parts makes the use of CR12 safe in any environment.

SV80 - Pneumatic decrimping machine

SV80 is designed for de-crimping all types of 1”aerosol valves available on the market. Useful in every laboratory, it recovers products and cans in case of wrong production. De-crimping action is done by a jaw connected to a pneumatic ram, which catches the valve and rips it. SV80 can also be used for de-crimping pumps from glass perfume bottles, however the results are not always successful; the glass perfume neck may be geometrically irregular or too low, in this case the pump can be only partially removed or the bottle breaks.

SV80 may be used in any environment as it is completely free from electrical components.

Manual Filling Machines

MD05 - Manual volumetric filling machine

Manual volumetric filling machine MD05 is designed for filling liquid through a volumetric glass piston of 30ml, therefore it is indicated for filling small vials or perfume mignons. On the eccentric of the piston the capacity to fill can be adjusted from 1ml up to 30ml. By a simple 90° lever movement the filling action is performed; being volumetric, MD05 can fill both glass or plastic containers.

MD07 - Manual volumetric filling machine

Manual volumetric filling machine MD07 is designed for filling liquid through a volumetric piston of 150ml, therefore it is indicated for filling perfume bottles of the standard capacities such as 50ml, 100ml and 150ml simply adjusting on the eccentric of the piston the capacity to fill. Being manual this machine is indicated for limited productions, where the precision is more important than the speed of filling. By a simple 90° lever movement the filling action is performed; being volumetric, MD07 can fill both glass or plastic containers.

Semi-Automatic Fillers

DV98 - Pneumatic vacuum filling machine

DV98 is a two nozzles vacuum pneumatically operated filling machine, able to fill liquids in any glass bottle shape and capacity through the use of vacuum; no electrical parts are involved. Cost efficiency, speed and minimum maintenance are its main characteristics. Special nozzles for mignon bottles and vials or large containers are available upon request, making DV98 a very flexible machine. The vacuum effect is not suitable for plastic containers, unless made of a very hard material.

DV098 - Pneumatic volumetric filling machine

Pneumatically operated volumetric filling machine DVO98 is designed for filling liquid through two volumetric pistons, where you can establish before filling, the desired capacity. This machine is not suitable for shampoo or creams or anything more viscous than liquids. Volumetric filling machines are very precise and the capacity of the pistons can be chosen based on each client needs, such as 50ml, 150ml, 250ml, 500ml. Being volumetric, DVO98 can fill both glass or plastic containers. The structure is manufactured in aluminum and stainless steel, the operation can be made by pressing a foot pedal or in automatic, simply changing the setting. This machine is suitable to work in any environment as no electrical parts are involved.

Diptube Cutting

Speedcut99 - Pneumatic Semi-automatic diptube cutting machine

Speedcut99 is an irreplaceable tool for cutting diptubes thanks to its simple mechanism and cost efficiency. By inserting the tube into a custom made hole and applying a slight pressure, an air switch triggers a small cylinder connected to a sharpened punch. Length adjustment depends on the positioning of the cutting apparatus, from a minimum of 30 mm to a maximum of 260 mm, the maximum diameter that can be cut is 6.4mm.

The cut is concave with a radius of 3.5mm, recommended for perfume diptubes. Speedcut99 can be powered by any compressed air supply given the limited amount of air necessary for its use. As a consequence, speed and productivity rates depend solely on the operator’s speed.

Collar Fitting Machine

CF01 - Semi-automatic pneumatic Collar pressing machine

CF01 is a simple solution for semiautomatic collar pressing on pumps.

Every time you change from one collar type or diameter you need to replace the plastic collar pressing insert into the machine head. The inserts provided with the machine are of 15mm, 18mm and 20mm diameter. The machine functioning is very easy: manually place your collar on your bottle pump after the crimping operation, then place the bottle on the machine base centering tool. The Machine operation will start by pressing two buttons at same time.

Testing Device

VTC - Vacuum Test Chamber

Coven VTC is a useful pneumatic device for testing the results of the tightening and crimping of bottles and containers.

The bottles are placed in the glass vacuum test chamber, and with the use of a venturi meter (-400/-600mm Hg), the correct tightening of crimp pumps or screw caps is tested.