Automatic Labelers

EconoLine Wrap Labeling System

Features

- Electronic platform: M2 or M3 microprocessor with encoder-based speed compensation

- 4-1/2″ width X 120″ length conveyor

- Variable speed wrap station for round containers. Available in 12″, 18″, or 24″ lengths.

- “No-tool” product changeover

- Stainless steel welded frame

- Production rate: Up to 150 ppm (dependent upon label/product dimensions)

- Applied accuracy: Up to +/-1/32″ (1mm) @ sigma 2

- Maximum product height: 14″ (356mm)

This EconoLine labeling system is a compact and economically-priced system designed specifically to apply a single label on a wide variety of round containers. This system is ideal for applications requiring up to 150 products per minute.

EconoLine features PLC control and color touchscreen operator interface. This provides ease of operation, electronic synchronization of the labeling process and storage of up to 20 label/product presets.

The “no tool” product changeover and modular design make the EconoLine ideal for packaging lines requiring frequent changeovers.

EconoLine Front/Back Labeling System

Features

- Electronic platform: M2 or M3 microprocessor with encoder-based speed compensation

- 4-1/2″ width X 120″ length conveyor

- “No-tool” product changeover

- Available with Stainless steel “no crevice” welded frame

- Production rate: Up to 150 ppm (dependent upon label/product dimensions)

- Applied accuracy: Up to +/-1/32″ @ sigma 2

- Maximum product height: 14″

This EconoLine labeling system is a compact and economically-priced system designed specifically to apply front and back labels on a wide variety of flat sided or oval containers. An optional third applicator may be added for front, back and neck applications. In addition, a wrap station may be added for round containers. This system is ideal for applications up to 150 products per minute. EconoLine features PLC control and color touchscreen operator interface. This provides ease of operation, electronic synchronization of the labeling process and storage of up to 20 label/product presets. The “no tool” product changeover and modular design make the EconoLine ideal for packaging lines requiring frequent changeovers.

TechLine Wrap Labeling System

Features

- 50 programmable product profile presets

- Onboard, non-volatile memory

- Stainless Steel welded Frame

- Four axis integrated labeling head support

- 12″ label unwind capacity

- 4.5″ x 10′ Stainless Steel conveyor (Available in 7″ widths)

- Stainless Steel Imperial fasteners

- Integrated Casters and Leveling Pads

- Variable Speed wraparound station with integrated encoder

- Product Spacing Wheel

- Optional Allen Bradley PLC control

The TechLine is a high performance, yet economically-priced labeling system for applying labels to cylindrical products of various diameters at up to 200 ppm. Built with quality, versatility and durability from the bottom up, the TechLine labeling system is engineered for ease of changeover and simplicity of operation. This system features Allen-Bradley© PLC Control, a color touchscreen operator interface, and all stainless steel construction.

TechLine Front/Back Labeling System

Features

- Compact Footprint

- 50 programmable product profile presets

- On board, non-volatile memory

- Stainless Steel welded Frame

- Four axis integrated labeling head support

- Labeling head and top hold down conveyor positioning scales

- 16″ label unwind capacity

- 4.5″ x 10′ Stainless Steel conveyor (Available in 7″ widths)

- Stainless Steel Imperial fasteners

- Integrated Casters and Leveling Pads

- Chain Aligners for oval bottle orientation

- Product Spacing Wheel

- Optional Allen Bradley PLC control

TechLine surpasses all equipment in its price range and is suitable for multi-shift operations where long-term reliability is important. This technically advanced front / back labeling system is designed to accommodate a wide variety of flat sided or oval containers. An optional third or fourth applicator may be added for front/back/neck applications or to provide non-stop zero downtime labeling. In addition, a wrap station may be added for round containers. Production rates of up to 250 ppm are possible with the TechLine. TechLine’s PLC control & color touch screen with Ethernet capabilities provides seamless integration into many demanding environments. Optional features such as servo driven label applicators, Allen–Bradley© Panelview touchscreen, servo driven product handling provides higher speeds and enhanced accuracy for the most demanding applications. The “no tool” product changeover and modular design make TechLine ideal for packaging lines requiring frequent changeovers.

ProLine Labeling System

Features

- Internationally compliant guarding

- All overhead mounted electronics

- Customer specified PLC platforms

- Color touchscreen operator interface with password protection

- 50 programmable product profile presets

- Emerson® servo driven top hold down conveyor

- Emerson® servo driven labeling stations

- Digital AC inverter motor drives

- Choice of Chain Alignment or Feed Screw bottle handling

Quadrel’s premium inline is system designed specifically for packagers of automotive motor oil. The ProLine features overhead electronics, internationally compliant guarding, servo driven components, Allen Bradley PLC control and PanelView color touchscreen. Additional features include all stainless steel construction, 14 inches of bottom clearance for easy clean up and speeds of up to 480ppm. This premium quality labeling system sets a new standard for pressure sensitive product labeling. The ProLine system was designed specifically for packagers that require globally supported internationally compliant factory standardization. Features include internationally compliant guarding, servo driven top hold down and labeling stations, non-proprietary Allen-Bradley© PLC control, touchscreen operator interface. Features include internationally compliant guarding, servo driven top hold down and labeling stations, non-proprietary Allen-Bradley© PLC control, touchscreen operator interface. Advanced features include pneumatic slides which reposition the applicators outside of the guarding during roll changes. This pulls the applicator away from the conveyor for ease of label change.

ProLine Zero Downtime Labeling System

Features

- Internationally compliant guarding

- All overhead mounted electronics

- Allen Bradley© PLC platforms

- Color touchscreen operator interface with password protection

- 50 programmable product profile presets

- Emerson® servo driven top hold down conveyor

- Emerson® servo driven labeling stations

- Digital AC inverter motor drives

- Choice of Chain Alignment or Feed Screw bottle handling

The ProLine high speed non-stop zero downtime labeling system features four servo driven applicators designed to accommodate a wide variety of flat panel, oval or round containers at speeds in excess of 300ppm. This premium quality labeling system sets a new standard for pressure sensitive product decoration. The ProLine labeling system was designed specifically for packagers that require globally supported internationally compliant factory standardization. Features include internationally compliant guarding, servo driven top hold down and labeling stations, non-proprietary Allen-Bradley© PLC control, touchscreen operator interface. Advanced features include pneumatic slides which re-position the applicators outside of the guarding during roll changes. This pulls the applicator away from the conveyor for ease of label change.

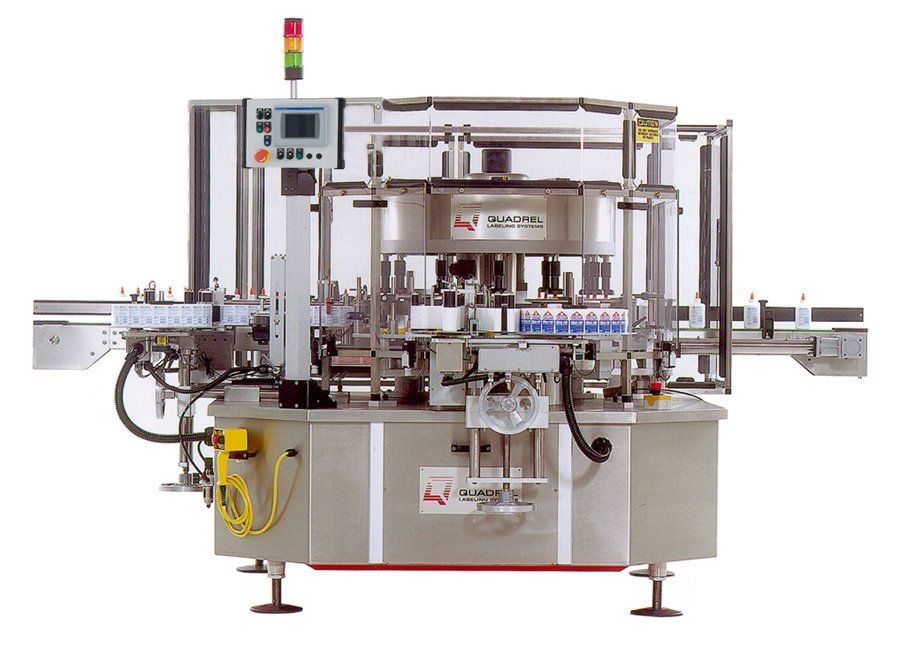

Rotary Labeling System - Front/Back/Neck Wrap

Features

- Full electrical integration

- Choice of mechanical, or servo controlled bottle platforms

- Full safety guarding with interlock

- Choice of Allen Bradley or low cost microprocessor controls

- Infeed and outfeed bank control sensors with integrated stop gate

- Feed-screw, star-wheel, and main carousel jam detection

This highly-advanced labeling system combines a 12-tool rotary base (816 mm dia. turret) with two high-speed servo driven label applicators. Features include full guarding, stainless steel construction, environmentally sealed electronics and a full complement of faults. This system is designed to accommodate up to four label applicators and is capable of applying front/back, wraparound, neck and spot labels at up to 350 products per minute. It may also be configured to automatically switch from one applicator to another for nonstop, zero-downtime production. Quadrel’s high-performance rotary labeling systems are available in several base sizes to accommodate virtually any speed requirements. Combination cold-glue/pressure sensitive systems are also available.