Fully Automatic

LA1

Automatic perfume filling and crimping line LA1 is the perfect and compact solution for an intense production.

The set-up of the machine can be custom made on each client’s needs, so different stations can be mounted on the machine depending on the different packaging needs. A transport belt of various length options, takes the bottles into a star wheel, where bottle cleaning, filling, pre crimping, crimping and collar pressing operations are performed. From the OP panel on the side of the machines all the operations are controlled.

STANDARD SET UP

- Bottle cleaning nozzle

- N°3 volumetric filling pistons

- Vacuum levelling nozzle

- Automatic pump fitting device

- Pneumatic pre-crimping device

- Pneumatic crimping device

- Automatic collar fitting device

- N°2 set of adjustable pucks for regular bottle shapes

- Incoming/out coming conveyor belt

OPTIONAL EQUIPMENT

- Screw tightening station for screw pumps

- Automatic vibrating pump and collar sorters (linear and circular)

- Manipulator “Pick and Place” device for automatic bottle charging / discharging

- External unit placed on transport belt for additional operations such as cap pressing

- Perfume Tank 30 liters

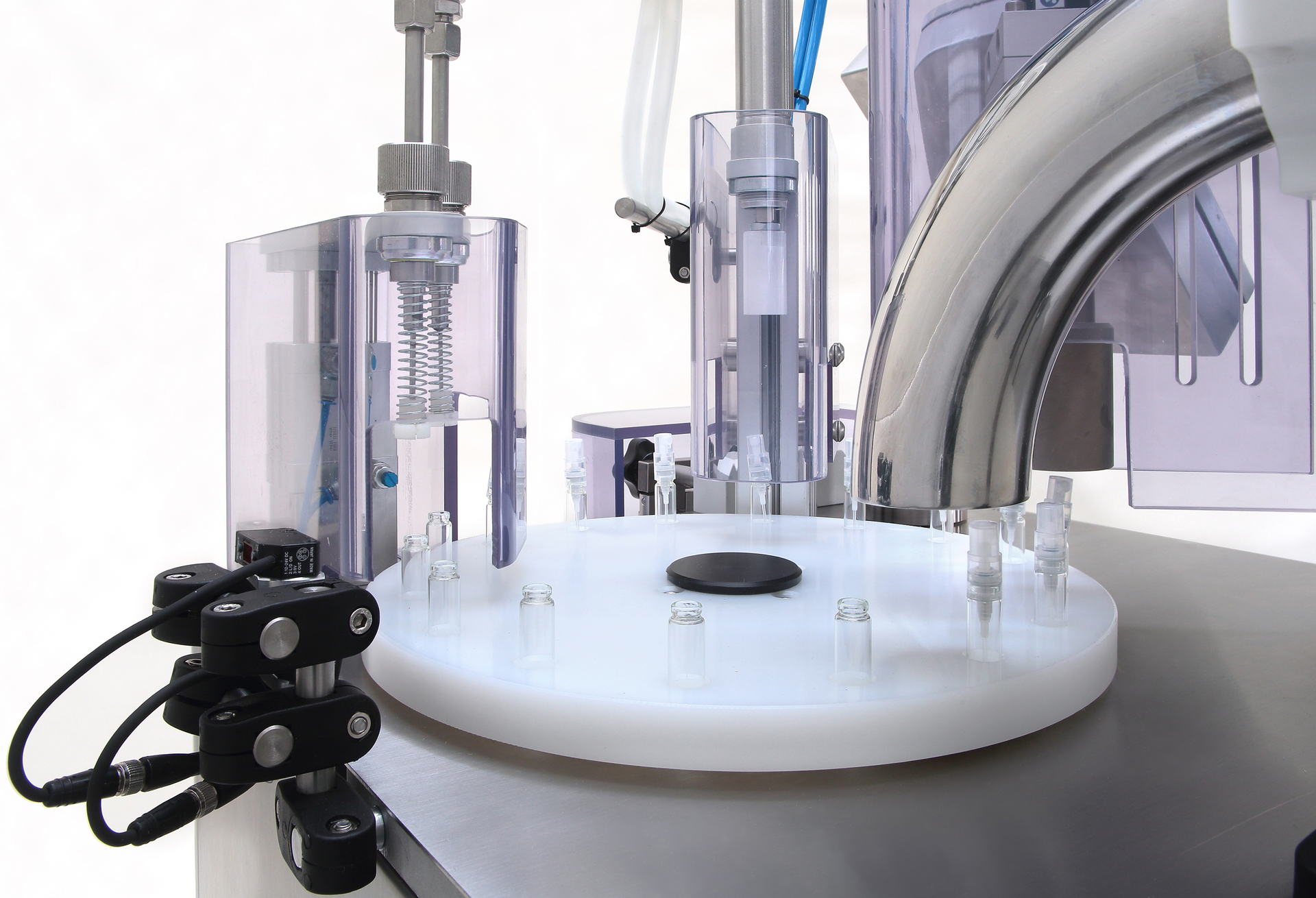

Miniline

MINILINE is designed for the packaging operations of small capacity perfume bottles, such as mignons and samples. The filling of the liquid is made by two volumetric pistons of 30ml capacity each (60ml total) on a 16 stations rotary star wheel for the bottle step movement; after the filling station, different operations can be placed, depending on each client’s need, such as cap pressing, crimping and screw tightening.

Motion is operated pneumatically and managed by an electronic system which simulates a series of mechanical cams. The control system is contained in a pulpit connected closely to the main structure of the machine. The electric motor supply and control panel is also fitted on the same structure.